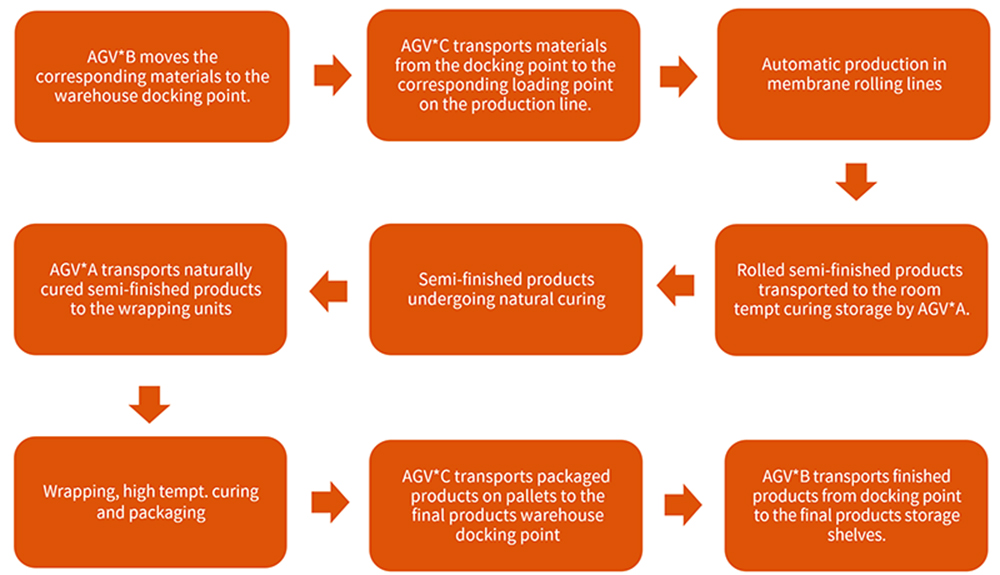

Foresight Tech offers an Intelligent Factory solution for manufacturing various industrial and municipal membrane elements. This fully automated system can produce low-pressure, nanofiltration, brackish water, anti-pollution, seawater desalination, and lithium extraction membrane elements. Key components include a Pre-Processing Rolling Line, Vertical Curing Storage, Post-Processing Assembly Line, AGVs, Vertical Raw Material Storage, Vertical Final Products Storage, an Informatization System, and a Central Control System.

Processes | Configuration N configured as per production capacity |

Pre-Processing Rolling Line | Folding Unit*N, Welding Unit*N, Rolling Unit*2N, Tube Feeding*N |

Vertical Curing Storage | Capacity configured according to the production requirements, and room temperature or constant temperature available. |

Post-Processing Assembly Line | Element Processing Unit*N, Wrapping Unit*N, Curing Oven*N, NG Shelf*N, Profile Inspection*N, Bagging*N, Racking*N, Cartoning*N, Palletizing*N |

AGVs | Forklift AGVs, Towing AGVs. AGV quantity configured according to production requirements |

Vertical Raw Material Storage | Capacity configured according to production requirements; Membrane sheets warehouse constant temperature and humidity |

Vertical Final Products Storage | Capacity configured according to production requirements |

Central Control System | Data center monitoring all line production data |

Informatization | Intelligent production and information management of the whole workshop. |