Innovations:

Industry's First Spot-Coating Technology

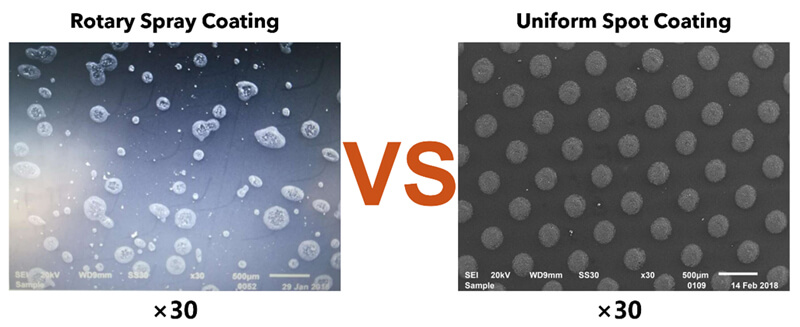

Precise Control: Controls the height and spacing of coating spots to improve coating consistency and effectively reduce the risk of lithium dendrite formation.

Increased Slurry Efficiency: Compared to spray coating, spot-coating can save over 30% of slurry for equivalent product performance.

Models

Model | Dimensions | Substrate Width | Heating Mode |

FST-CM-BS-100 (Single-Sided Coating ) | L24.5m×W6m×H5m | 1.3 m | Electric/Thermal Oil/Steam |

FST-CM-BS-200 (Double-Sided Coating) | L32.5m×W6m×H6m | 1.3 m | Electric/Thermal Oil/Steam |

FST-CM-BS-101 (Single-Sided Coating) | L24.5m×W6m×H5m | 1.5 m | Electric/Thermal Oil/Steam |

FST-CM-BS-202 (Double-Sided Coating) | L32.5m×W6m×H6m | 1.5 m | Electric/Thermal Oil/Steam |

Specifications

Parameter | Specifications |

Coating method | Roller Coating/Spray Coating/Spot Coating |

Coating width | Max. 1500 mm |

Coating speed | Max. 200 m/min |

Substrate thickness | 5-16 μm |

Reel diameter/weight | Max. Φ600 mm/250 KG |

Mechanical speed | 250 m/min |

Roller width | 1650 mm |

Dryer Temperature | Max. 120 ℃/±1 ℃ |

Integrated Heat Sources: Combines infrared, ceramic, and other heat sources for higher thermal exchange efficiency.

Efficient Thermal Insulation: Features a lighter heat bridge to reduce thermal conduction, with new materials that decrease thermal radiation.

Intelligent Adjustment: Reduces wrinkles and slippage at the roll's bottom, ensuring proper tension at all stages and reserving space for separator shrinkage.

Rapid Data Utilization: Utilizes AI to quickly access historical data, minimizing adjustments and reducing scrap rates.

Diverse Materials: Compatible with various water-based ceramics and PVDF/PMMA combinations.

Diverse Coating Methods: Supports roller coating, spot coating, and spraying, among others.

Modular Design: Ensures seamless integration.

Automated Data Collection: Eliminates manual data entry and can be integrated with MES systems for seamless data transmission.