FST-CM-WTM-101 Intelligent Precise Membrane Casting and Coating Manufacturing System is a fully automated manufacturing solution provided by Shanghai Foresight Technology Co., Ltd. for Membrane Enterprise.

FST-CM-WTM-101 includes rewinding/unwinding unit, coating unit, water tank unit, dryer unit, membrane sheet detection unit, correction system, tension system, control system, information system, error alarm processing and safety protection system.

Parameters | Specifications |

Maximum Speed | 20 m/min |

Substrate | Non-woven |

Substrate Width | 1044/1070 mm (41/42 inch) |

Unwinding Diameter Range | 200-500 mm |

Winding Diameter Range | 100-500 mm |

Unwinding/Winding Tension Range | 50-250 N (<±10%) |

Dimension | L60 m*W11 m*H8 m |

With this technology, the detection, control, feedback and execution are precise and efficient, which enables the film to be precisely controlled in long-distance transmission, improves the flatness, uniformity and other performance indexes of the film, and improves the stability of the equipment.

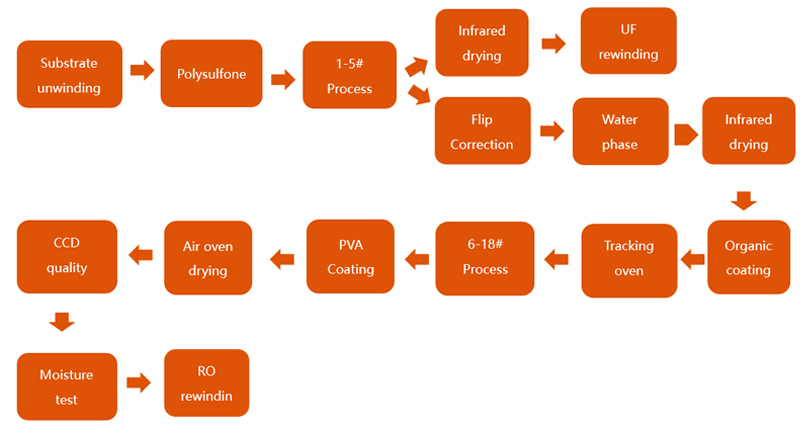

The casting and coating functions are modularized, which can be combined as a whole or operated separately according to the demand. Through solving the problems of cycle time balancing and the smooth conversion of various types of membrane switching in production, UF, NF, and RO membrane can be produced efficiently.

The length of the membrane can reach 280 meters. Through efficient tension control to achieve micron-level regulation between the coated membrane lip and the substrate, the uniformity and consistency in thickness of each coated layer are ultimately ensured, which reduces the defects on the surface and ensures the quality of the product.

The guide roller in the tank can be lifted as a whole, therefore, during production, maintenance can be easily made, which is convenient for cleaning; No need to discharge solvents, to save production materials; when threading membranes, it can realize fast threading without other operations, convenient for operation and maintenance.

Composed of machine vision and AI algorithms, the automatic inspection system learns and optimizes the degree of film defects, which can accurately detect the defects, and automatically mark the defects on the membrane, making its quality effectively guaranteed.

The equipment realizes the coating function effectively and accurately through the precise process control system and the whole PID adjustment, as well as number of intelligent technologies, such as intelligent monitoring of product quality, warning and troubleshooting instructions, order management system, one-key start/stop, and one-key changeover of the product, etc. added, which makes the equipment easier to be operated and maintained